The Art of Making Jewelry Chains: From Raw Material to Finished Product

By: Leslie H.

Jewelry chains are a staple of the jewelry industry, and they come in a wide variety of styles, sizes, and materials. But have you ever wondered how these chains are made? In this article, we'll take a closer look at the process of making jewelry chains, from the raw materials to the finished product.

Step 1: Choosing the Right Material

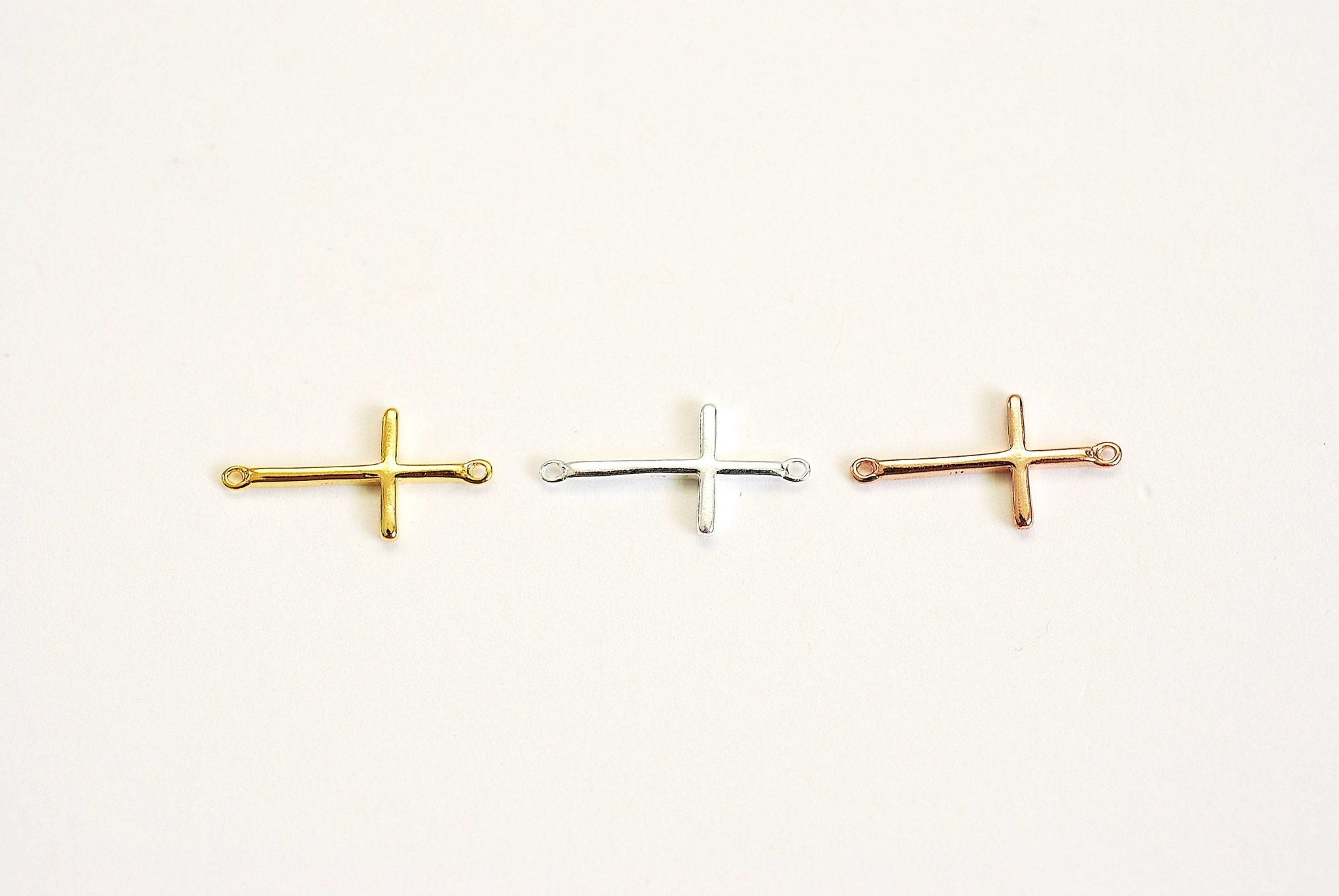

The first step in making a jewelry chain is to choose the right material. Chains can be made from a wide range of materials, including precious metals like gold and silver, as well as base metals like copper, brass, and stainless steel. The material chosen will depend on factors like the desired style, durability, and cost of the finished chain.

Step 2: Creating the Wire

Once the material has been chosen, the next step is to create the wire that will be used to make the chain. This typically involves a process known as drawing, in which a block of metal is pulled through a series of progressively smaller holes until it reaches the desired thickness. The wire is then cut into shorter lengths, which will be used to create the individual links of the chain.

Step 3: Shaping the Links

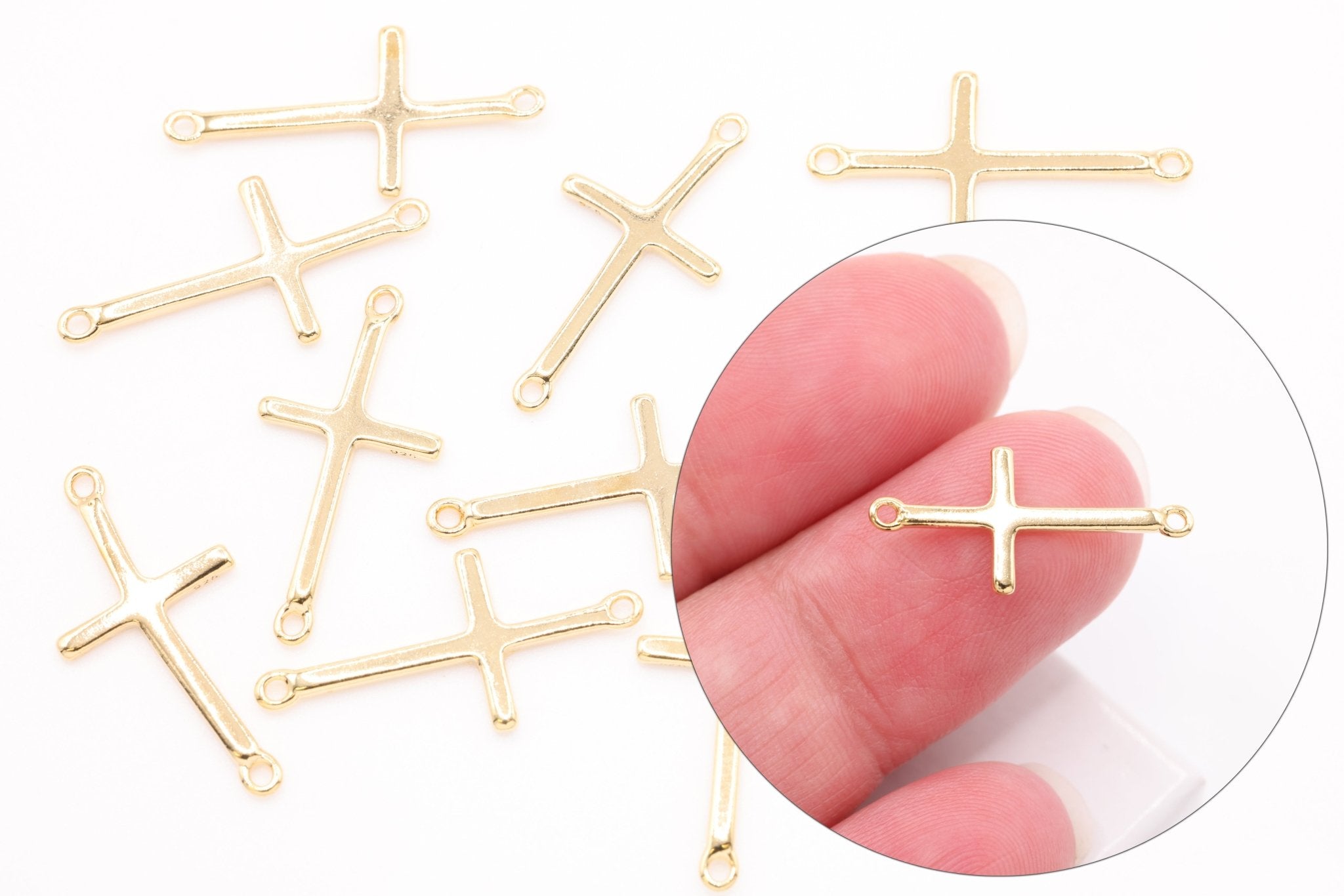

The next step in the process is to shape the wire into individual links. This is typically done using a variety of tools, including pliers, hammers, and mandrels. The links may be round, oval, or even square, depending on the desired style of the finished chain.

Step 4: Assembling the Chain

Once the links have been shaped, the next step is to assemble them into a chain. This is typically done by connecting the links together using a variety of techniques, including soldering, welding, or simply bending the links to interlock with one another.

Step 5: Finishing the Chain

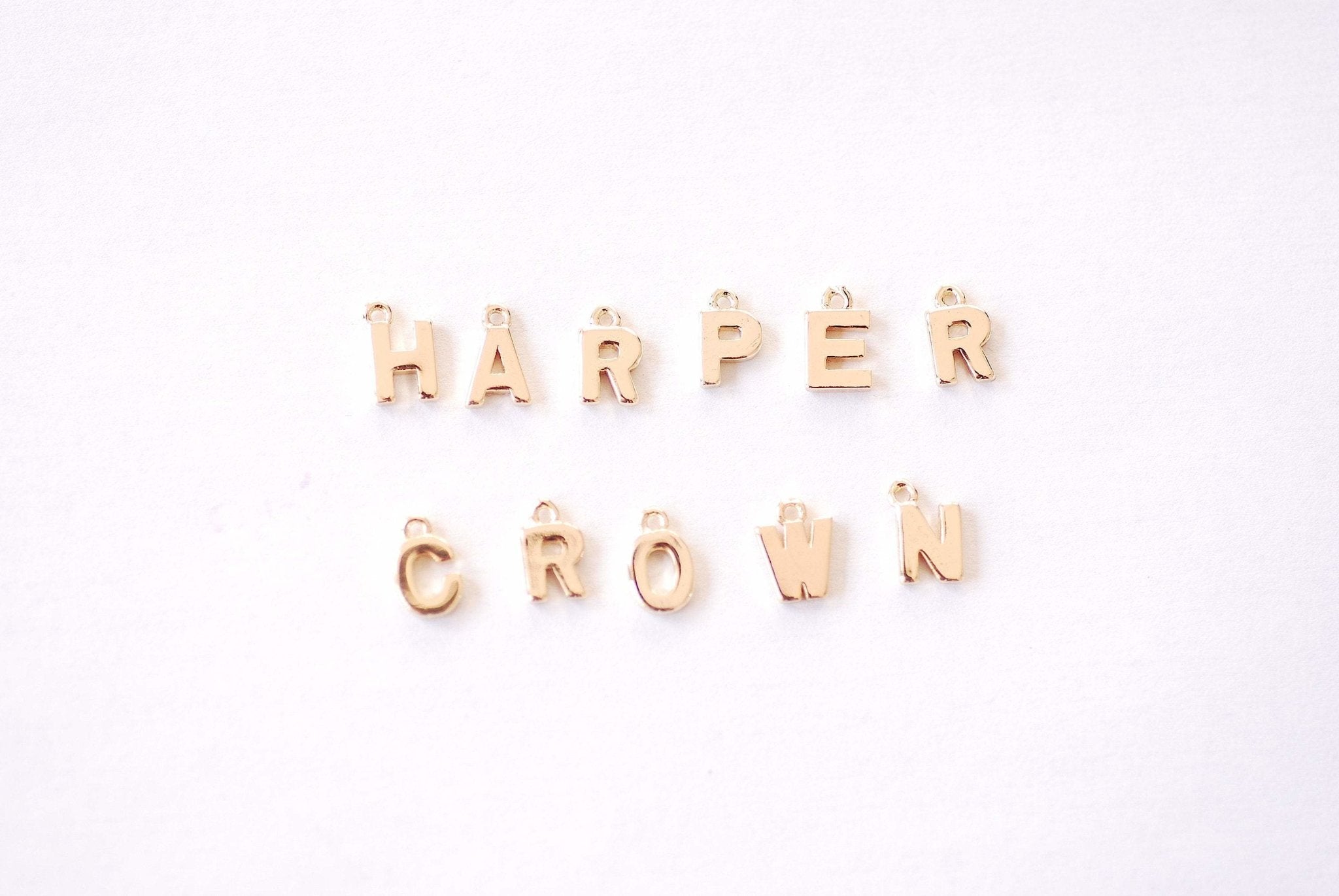

The final step in the process is to finish the chain. This may involve polishing, plating, or adding decorative elements like beads or pendants. The finished chain is then inspected for quality and packaged for sale.

Variations on the Chain-Making Process

While the above process is a general overview of how jewelry chains are made, there are many variations and techniques that can be used to create different styles of chains. For example, some chains may be made using a weaving or knitting technique, rather than individual links. Others may be made using a combination of different materials, such as a chain that incorporates both metal and leather.

Factors that Affect the Quality of a Jewelry Chain

The quality of a jewelry chain depends on a variety of factors, including the material used, the thickness of the wire, and the quality of the manufacturing process. A high-quality chain will be durable, resistant to tarnishing or rusting, and will have a smooth, polished finish.

Caring for Your Jewelry Chain

To ensure that your jewelry chain lasts as long as possible, it's important to take proper care of it. This may involve storing it in a cool, dry place to prevent tarnishing or damage, cleaning it regularly using a soft cloth or polishing cloth, and avoiding exposure to harsh chemicals or abrasive materials.

Conclusion

Jewelry chains are an essential component of the jewelry industry, and they come in a wide variety of styles and materials. The process of making a jewelry chain involves choosing the right material, creating the wire, shaping the links, assembling the chain, and finishing the chain. By understanding the process of making a jewelry chain, you can gain a greater appreciation for the skill and craftsmanship that goes into creating these beautiful pieces of jewelry.